Over the years, most equipment manufacturers in the cement industry have mostly used electromagnetic speed regulation, which consumes a lot of energy. High-performance and low-performance cement products continue to enter the market. These energy-inefficient devices are running all the time, consuming a lot of electricity. Therefore, the rapid development of frequency conversion products has also been accelerated, and the pain points of the original equipment have been solved.

Centrifugal cement pipe is one of many cement products. There are various production processes. In order to ensure the uniformity and compactness of the wall thickness of the cement pipe, the most common production and processing process is the centrifugal molding method. Centrifugal molding is to inject the finished concrete into the mold cavity. First, it is stirred at a low speed. After stirring evenly, the motor speed is increased to a medium speed.

| Parameter | Description | Set Value | Remarks |

| F0.00 | Control Mode | 1 | V/F Control |

| F0.01 | Start/Stop Source | 1 | Digital Input Terminal(External Signal)DI1 |

| F0.03 | Main Frequency Source | 2 | Analog input Terminal AI1 |

| F0.18 | Acceleration Time | 200 | 200s |

| F0.19 | Deceleration Time | 200 | 200s |

| F1.11 | DC Braking Frequency at Stop | 4 | Activate DC braking function at stop in 4HZ |

| F1.14 | DC Braking Time at Stop | 5 | DC braking function lasts for 4s |

| F4.00 | V/F Curve Option | 1 | Multi-point V/F curve |

| F4.04 | V/F Voltage Point 1 | 13 | V/F Voltage Point 1=13% |

| F4.06 | V/F Voltage Point 2 | 16 | V/F Voltage Point 2=16% |

| F4.08 | V/F Voltage Point 3 | 25 | V/F Voltage Point 3=25% |

| F5.02 | DI3 Terminal Function Option | 3 | Three-wire Running Control |

| F5.16 | Terminal Command Method | 2 | Three-wire Running Control Mode 1 |

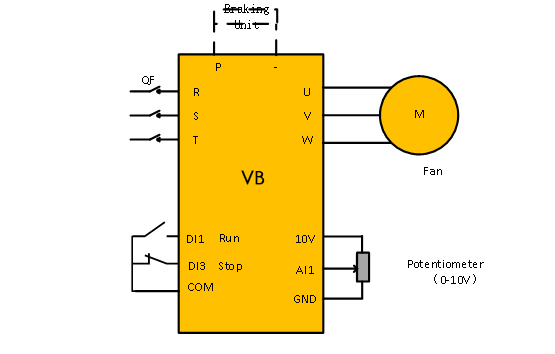

1. The startup mode of VB is stepless speed regulation mode, which reduces the impact of high current on the motor.

2. Utilize the VB multi-point V/F curve function to meet low speed torque and reduce energy consumption.

3. Use VB stop braking function to increase system stability and improve efficiency better.

4. The VB itself has protection functions such as overload, overcurrent, overvoltage, phase loss, etc., which better improves the safety of the equipment.