Today, there are many ready-to-eat egg foods, such as our favorite braised eggs, quail eggs, etc., which can be described as dazzling in supermarkets. In order to meet people's needs, the industrial production line of eggs bears the brunt and is responsible for important production tasks. The production line with frequency conversion speed regulation, its production capacity is obviously higher than that of ordinary production lines. The following introduces the application of VB in a certain boiled egg automatic production line.

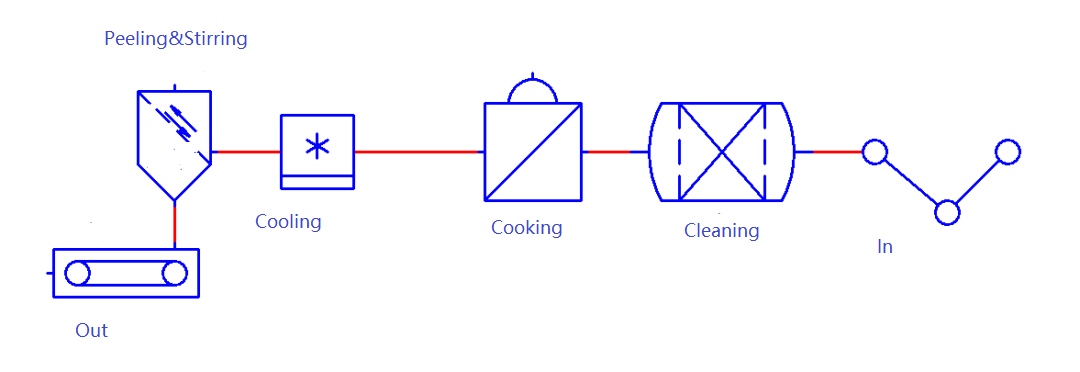

From right to left as shown in the figure, after the eggs are loaded, they are lifted by the water tank and transported to the egg washing machine. The cleaned eggs are transported to the cooking section through customs inspection and puncture, and the boiled eggs are transported to the cooling section, and then lifted by the conveyor belt. To the peeling machine, finally output boiled eggs without skin, and the peeled egg skin is automatically discharged.

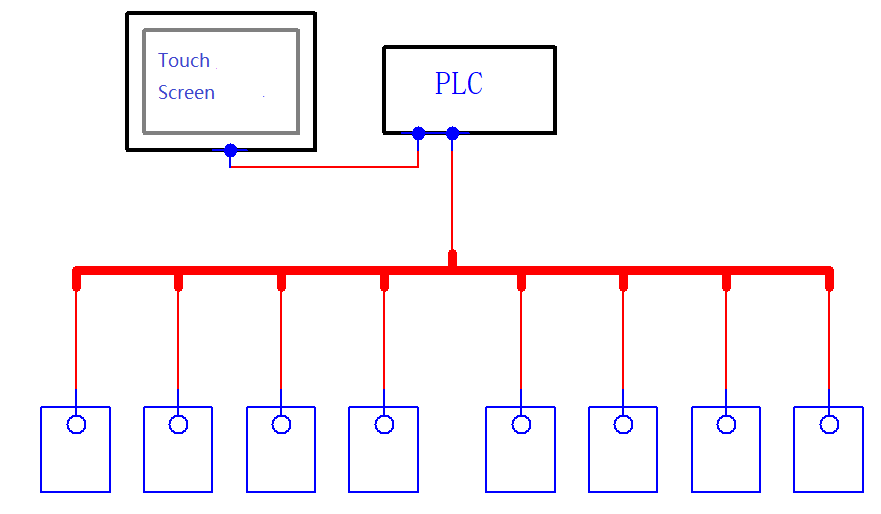

Control overview: This production line is equipped with 16 sets of VB VFDs, which are divided into two parts for control, among which:

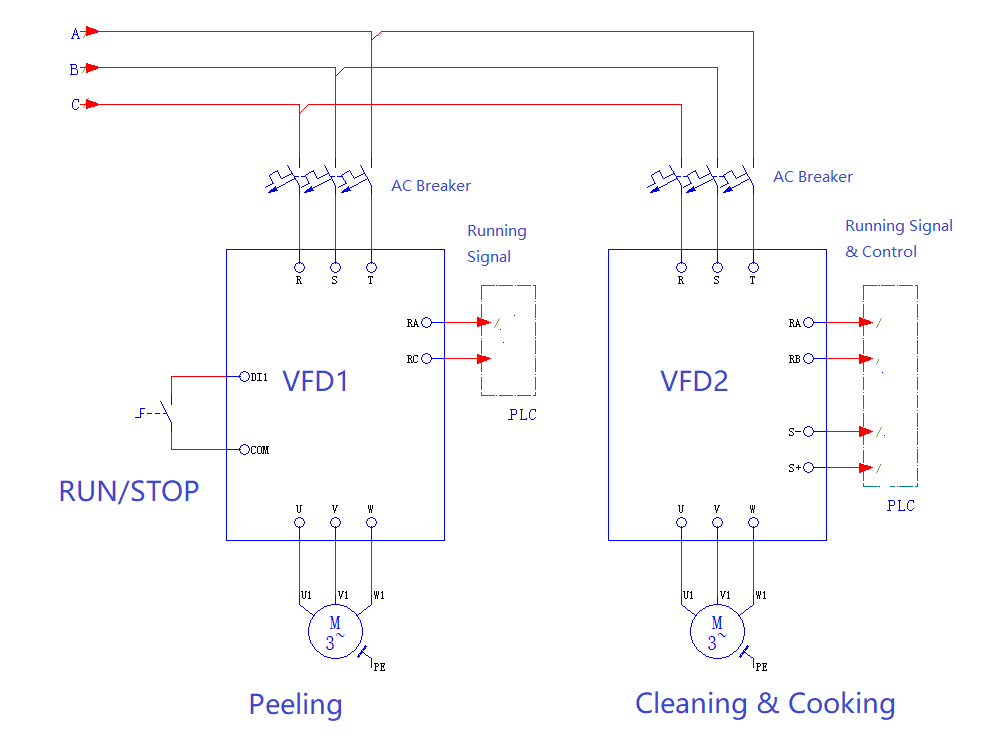

Peeling part: 8 frequency converters, controlled by a rotary switch, the control mode is manual; the start and stop are realized by the switch beside the machine, and the speed regulation is realized by the panel potentiometer. Responsible for controlling the vibrating screen motor, egg input motor, egg output motor, and egg skin output motor of the peeling machine, two for each.

Cleaning and cooking part: 8 frequency converters, centrally controlled by PLC, the control mode is RS485 communication; start-stop, speed regulation are realized through touch screen input.

Peeling Part:

| Parameter | Description | Set Value | Remarks |

| F0.01 | Start/Stop Option | 1 | Terminal Start/Stop |

| F6.02 | Relay 1 Output Option | 1 | VFD Running |

Cleaning & Cooking:

| Parameter | Description | Set Value | Remarks |

| F0.01 | Start/Stop Option | 2 | Communication Start/Stop |

| F0.03 | Frequency Source | 9 | Communication |

| F6.02 | Relay 1 Output Option | 1 | VFD Running |

| FC.00 | VFD Address | 1~247 | User-Defined |

Increase productivity. Because the motors of each part of the production line are controlled by frequency conversion, the speed of the conveyor belt in each link is controllable, and the input and output speeds of materials are also adjustable and controllable, avoiding material accumulation and waiting, and greatly increasing production efficiency.

Cut costs. VB standard RS485 communication interface and MODBUS communication protocol are convenient for PLC centralized control, and workers can operate multiple links through a human-machine interface, which is intuitive and convenient, with a high degree of automation and saves labor costs.

Extend equipment life. VB's over-current protection, over-voltage protection, overload protection and other functions can effectively protect the motor, prolong the life of the motor and machinery, and reduce maintenance costs.