In 2024, the global dairy food market was valued at US$947.1 billion. The market is projected to grow from US$1,005.84 billion in 2025 to US$1,524.65 billion by 2032, at a compound annual growth rate of approximately 6.12%. The Asia-Pacific region held a 41.02% market share in 2024. Furthermore, the US dairy market is expected to reach US$134.57 billion in 2032, driven by increasing demand for cheese, milk, and yogurt products. The dairy industry encompasses milk production, sales, and the manufacturing of dairy products such as yogurt, cheese, butter, and ice cream. Due to the high nutritional value of milk and related foods, the demand for these products continues to grow.

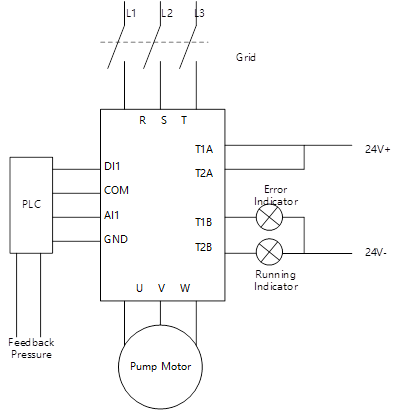

The water supply system is crucial for many processes within the plant, including dairy farming, pasteurization, dairy product manufacturing, and wastewater treatment. Traditional control methods involve adjusting valve openings to obtain the required pressure and flow rate, but this is inefficient, inconvenient, and leads to wasted electricity. After installing the VFD the speed of the water pump motor can be directly adjusted, thereby achieving pressure and flow control. For more intuitive operation and monitoring, a constant pressure water supply controller integrating a PLC and a display screen can be used. It receives feedback signals from the pressure sensor, performs PID calculations, and directly outputs a 0-10V analog signal to the variable frequency drive for speed control. The display screen directly shows the current system status, various parameter values, and fault records in text format.

| Parameter | Description | Set Value | Remark |

| F0.01 | Start/Stop Command Source | 1 | DI Terminal |

| F0.03 | Main Frequency Source | 2 | AI1,0-10V |

| F2.01 | Motor Rated Power(kW) | Motor label | |

| F2.02 | Motor Rated Voltage(V) | ||

| F2.03 | Motor Rated Current(A) | ||

| F2.04 | Motor Rated Frequency(Hz) | ||

| F2.05 | Motor Rated RPM(rpm) | ||

| F6.02 | Relay 1 Option | 02 | Alarm Output |

| F6.03 | Relay 2 Option | 01 | Running Output |

5. Photos at Site

1) The VFD has dual relay terminals, enabling output of running and alarming status without the need for external relays. This simplifies wiring for indicator lights in the control cabinet, providing a clear display of system status and facilitating inspection by plant operators and maintenance personnel.

2) The VFD includes a built-in soft start function, ensuring smooth starting current and preventing shocks to the power grid and water supply network, thus extending the system's service life. Digital and analog input terminals seamlessly connect with the upper-level PLC, eliminating the need for complex parameter settings.